|

The

Trend Setter

Part

3

ONE-WIRE

compared to

THREE-WIRE

ALTERNATORS

What Happens when the

ONE-WIRE cannot do Remote Voltage-Sensing

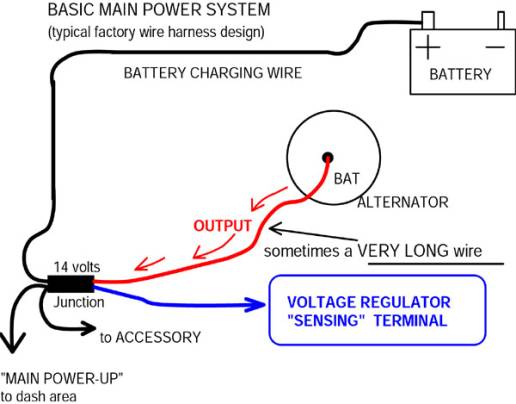

All voltage regulators

for alternator systems will have a “VOLTAGE SENSING”

terminal. The

voltage regulator for the “ONE-WIRE” system gets the

voltage reading from within the alternator, and it will

maintain the alternator out-put terminal at about 14.2

volts. Lack

of compensation for voltage drop that will occur with a

long wire routed to a “MAIN POWER DISTRIBUTION

JUNCTION” is the problem with being able to read voltage

only at the alternator.

In many factory-original wiring systems, the

entire electrical system will draw power from the main

junction, and the battery will charge from the

main junction too. If we have a 2.5 volt drop in the long length of wire between

the alternator and the “main junction,” and start out

at the alternator with 14.2, then we only have 11.7 volts

at the main junction. Expect dim lights, weak ignition, and slow electric

radiator fans with this system being powered by a

“ONE-WIRE” alternator.

Please note

that simply disconnecting the original alternator wires,

and then installing a heavy cable from the alternator

directly to the battery, will only make the alternator

effective as a “battery charger.”

(That happens when running a ONE-WIRE alternator

with many factory layouts.)

Of course we have to charge the battery, but what

about routing power from the alternator to the electrical

system? (ignition,

lights, and accessories)

Power would have to flow from the battery to the

junction via the old “charging wire.”

And often in a factory-original type harness the

“charging wire” is even longer than the wire from the

alternator to the junction.

And so the result of this ONE-WIRE method would be

dimmer lights and overall weak electrical system

performance; in fact often worse performance than with the

original, correctly wired, small alternator that was

standard equipment on the old cars.

Okay, all these modern

accessories that come with instructions to connect a wire

directly to the battery POS, and the instruction to

connect a cable from the ONE-WIRE directly to the battery,

has resulted with a clutter at the battery area.

And thanks to the 100 amp ONE-WIRE alternator (a

high rate battery charger indeed), the wires are a

corroded, unreliable, mess!

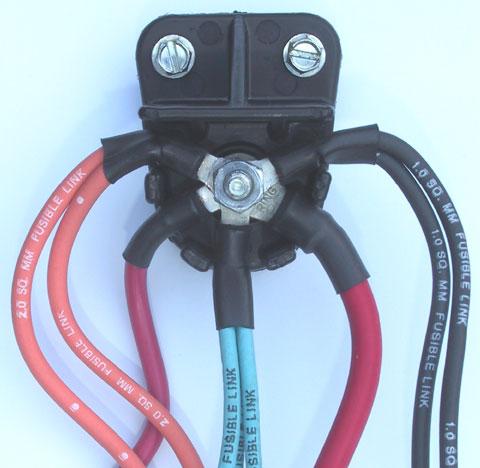

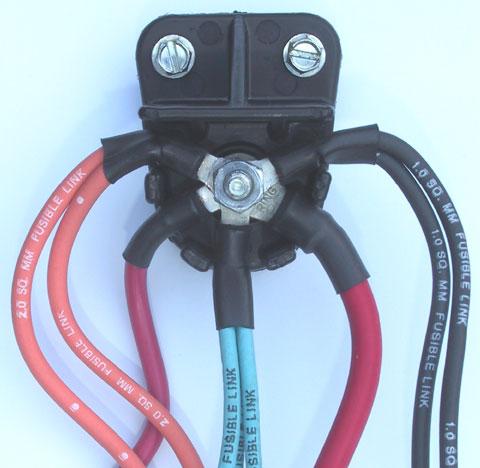

The part#CN-1, insulated

terminal block, from M.A.D.’s catalog, is a sensible

method of connecting a few wires together.

It has a re-enforced shield above it to shed water,

and separators between wires.

It’s a great little organizer in general.

And it will be mounted remote from the battery,

where it will stay free of corrosion.

Value of Remote

Voltage-Sensing with THREE-WIRE

The well laid-out factory

system will have the voltage regulator taking the

“VOLTAGE SENSING” sample directly from the “MAIN

JUNCTION,” through a wire dedicated to this function.

And that was true with both the external and the

internal voltage regulator systems.

And it’s the reason that the old external voltage

regulator stayed at the driver’s side when the

alternator got moved to the opposite side, beginning with

’69 models (Chevy V-8 engines).

As lighting or any

accessories are switched ON, more power is drawn from the

main junction, which would lower voltage at the junction.

But the voltage regulator will increase alternator

output as needed to maintain the 14 volt level at the

junction. If

we have a 2.5 volt drop in the wire between the alternator

and the junction, then the voltage regulator will make the

alternator produce 16.5 volts to compensate for the

voltage drop with routing of power to the junction.

It’s a somewhat

“spongy” system, but it does work well and the

alternator doesn’t know the difference.

Expect bright lights, strong ignition, powerful

accessories, and a properly charged battery when this

system is wired effectively.

When running with the factory-original type wire

harness, clearly it is an advantage to maintain the

“MAIN POWER DISTRIBUTION JUNCTION” at 14 volts.

ELECTRICAL SYSTEM

PERFORMANCE

When voltage available to

electrical parts drops about 10% below optimum level, the

performance of the parts will typically drop by about 30%.

If voltage delivered to parts is only a little low,

performance can be very weak.

(Lights will be dim, electric fans will not move as

much air, fuel pumps will be low with fuel pressure

delivery, and so on, when these parts operate at low

voltage.) Most

automotive electrical parts are rated at about 14 volts.

And the parts will deliver best performance and

last the longest when operating at 14 volts.

A couple of very

important considerations

regarding this

factory-original type system, which uses a main power

distribution junction, and remote voltage sensing.

(And of course M.A.D.

did not invent the system, we are just observing operation

of a system that was successfully used for many years.

And it is a system that we understand well enough

to up-grade, make it friendly for addition of accessories,

and make it stronger to accommodate a more powerful

alternator operating more powerful accessories.)

(1)

The system only works properly when the “battery

charging wire” connects from the junction to the

battery. There

will never be a wire connected from the alternator

directly to the battery.

By now the thought may

have occurred, that a possible installation could include

a heavy gauge charging wire from the alternator directly

to the battery. And

then leave in place the original wire from the alternator

to the factory main junction. Route the voltage sensing

wire to the junction, in effort to keep the lights and

ignition happy. It’s

true that then voltage regulator would maintain the

junction at the 14.2 level.

However, the fault in the plan is with the voltage

drop that will occur between the alternator and the

junction. As was previously discussed, the system will

compensate by raising the voltage level at the alternator.

The problem would be overcharging the battery

through the separate charging wire, as voltage at the back

of the alternator could be over 16 volts.

(2)The

second important consideration of the typical Muscle Car

period factory system is the effect of the long battery

charging wire (which routes from the junction to the

battery). It’s

a rare occasion when a little resistance in wiring can

actually help us, and this is one of those rare occasions.

A small amount of resistance in the “charging

wire” leg of this system will serve as a cushion.

The amount of resistance will be much too small to

be measured with an ordinary ohmmeter, as accuracy of the

ohmmeter will only be good to about a plus or minus 0.2

ohm. But the

amount of resistance can be calculated after measuring

current flow and voltage drop.

To understand how this

“cushion” effect with a small resistance at the

charging wire works, we must first have knowledge of how

batteries behave when being charged.

When recharging a low battery, battery voltage will

be low, and current flow (amps) to the battery will be a

large amount. As

the battery becomes charged, battery voltage increases,

and it will accept less charge, so charging current (amps)

will decrease. Eventually

during charging, battery voltage reaches the level of the

voltage setting at the charger, and the battery stops

accepting all but a very small amount of current.

(See more about how

discharged batteries behave when being charged, in photos

and captions, at our “RE-CHARGING LOW BATTERIES” page,

in this tech section.

And see more about special maintenance battery

chargers at our BATTERY CHARGING for MAINTENANCE and

STORAGE page in this tech section.)

When working with more

than a 60 amp alternator, the actual amount of resistance

at the “charging wire,” and also the wire from the

alternator to the junction, should always calculate to

less than 0.1 ohm. The

actual amount of resistance will vary with wire length and

wire gauge sized used in various models, and the amount of

resistance will also change with temperature.

(A warm wire conductor will have more resistance

than a cool wire conductor.)

A new or good condition, factory built harness on a

Chevy from the Muscle Car period will have about 0.02

to 0.05 ohm resistance at the wire from the alternator

to the junction, and about the same at the charging wire

from the junction to the battery.

RESISTANCE IN THE

“CHARGING WIRE” /

FULLY CHARGED BATTERY

For our calculations, we

will use a 0.05 ohm resistance, which is a

middle-of-the-road number, for an average Chevy factory

harness. The

battery will be charged from the junction in the wire

harness, and voltage at the junction will be maintained at

14.2 volts. With

the battery in a fully charged condition, it will accept

less than 1 amp, from a 14.2 volt source.

We will use 1.5 amp for the charge rate, which is a

battery approaching fully charged condition.

The math formula (from Ohm’s Law) can be used to

easily calculate the amount of voltage drop that will

occur with the small amount of resistance at the

“charging wire” between the junction and the battery.

The math formula gives us that Voltage (drop) =

current flow (amps) X resistance (ohms).

With the numbers used for this example, 1.50 amps X

0.05 ohms = 0.075 volt(drop).

Rounded off to the nearest 1/100th of a

volt, that is a 0.08 volt drop.

And so, with 14.20 volts at the junction, we have

14.12 volts at the battery, which is fine.

(Individual voltage regulator settings will vary

more than 0.08 volts.)

The small amount of resistance in this wiring

system does not have significant effect on charging the

battery, when the battery becomes fully charged.

Voltage drop is a very small amount, when the

current flow is a small amount (through the small amount

of resistance at the charging wire).

RESISTANCE IN THE

“CHARGING WIRE” /

DISCHARGED BATTERY

When charging current is

delivered to a discharged battery at a full 14.2 volt

level, the battery will accept a large amount of current

(amps). And

when charging a large capacity battery, if the battery

charger or alternator is sufficiently powerful, the amount

of current can be a large amount.

In that case we can expect the battery to get warm

and produce excessive gas (which results with short

battery life and a corroded mess at the battery area).

The battery charger or alternator will produce a

significant amount of heat too, so it will need a good

cooling capacity. (With

both the battery and the alternator, it’s back to that

efficiency loss situation where heat is the by-product.

The low battery

being charged by the alternator is a situation when the

small amount of resistance in the charging wire will help

us. Power

from the junction will reach the battery at a reduced

voltage level; which automatically reduces the charge

rate. We could do calculations for this situation, like we did

above with demonstration of system performance when the

battery is fully charged.

However with the discharged battery situation we

don’t have constants.

Resistance in the

charging wire causes voltage drop with current flow to the

battery, and the voltage drop reduces current flow.

Current flow is also reduced as the battery becomes

charged. We

begin with a discharged battery that cannot produce full

voltage on its own. Then

as the battery accepts current it becomes more charged and

produces more voltage, and then the battery accepts less

current flow. In

this battery being re-charged situation, the system is not

“static,” it is a changing and self-adjusting system.

The small amount of resistance at the “battery

charging wire” makes it is a very gentle and

“forgiving system.”

The system is

conservative as it helps to prevent battery gassing,

battery overheating, and alternator overheating. The small

amount of resistance in the “charging wire” does not

prevent the battery from reaching a fully charged

condition; with a small resistance it will just take a

little longer to top off the battery with charge.

(And when using a 100 amp alternator, it can be a

very good idea to slow down the charging rate!)

And…while

all the above is happening, ignition, lighting, and

accessories are being powered-up from the main junction,

and at a 14 volt level–and 14v regardless of battery

condition! (The exact voltage level will be the setting of

the voltage regulator, and we assume that the alternator

is capable of operating all the accessories plus charge

the battery). All

aspects, considered the factory layout using a “main

junction” and “remote voltage sensing” is an

incredibly effective system.

Although when the alternator is replaced with a

more powerful model, and added accessories draw more power

from the system, then the wiring for the system must also

be up-graded.

It has never been a

good idea to re-charge a low battery with the alternator.

But there are those times when we are caught by

surprise… It’s easy enough to accidentally leave the

lights on when far away from home.

Or an electric fan run-on function can run the fans

longer than the battery can stand.

Eventually the time can arise when we need a

jump-start, and then we will drive to our destination.

And with a high powered alternator in place, these

are the times when a system like the factory lay-out with

a properly wired THREE-WIRE alternator system could really

help us out, by slowing the charge rate.

(A low battery should be re-charged with a workshop

type charger. The

alternator is intended to keep the battery topped off and

operate the electrical system.)

A POSSIBLE PROBLEM

with installing a more powerful alternator and

using the existing factory wiring is that when those older

cars were built, the wire gauge sizes were calibrated for

much less powerful alternators than we are using today.

And back when those cars were built, we were not

operating so many powerful accessories.

Nowadays electric radiator fans are a common

example of an added accessory that will strain the

existing system.

Voltage

drop resulting from a small amount of resistance spread

out over a long length of wire will behave quite

differently than a small amount of resistance at a

“bottleneck.” With

voltage drop, the electrical energy lost is converted to

heat. (Again,

energy is never lost or destroyed–only converted.)

In the case of a short length, under-capacity wire,

or in the case of a poor connection, we have resistance at

a small area, and this bottleneck effect can result with

destruction of the part through “thermal run-away.”

When we spread the small amount of resistance out

over a long length of wire, the voltage drop and heat

generated is also spread out over the length of the long

wire; and then the heat can be dissipated without

overheating the wire.

But as with stress limitations of any machinery

part, there are limitations with this wiring system too.

(A thorough discussion and explanation of

“thermal run-away” effect is contained in the “tech

is made simple” book, available from M.A.D.

A

typical ’65 Chevy was often shipped with only a 37 amp

alternator, and the wiring was adequate for that much

output. The

wire from the output terminal of the alternator was often

only 12 gauge, with early alternator systems.

The wiring will have to be up-graded on those early

cars, when we use more powerful alternators and

accessories.

The

current capacity of factory systems in various cars from

the Muscle Car period will differ considerably.

But Chevy is more popular than ever before; we will

use Chevy for an example. The ’69 –’71 Chevy with V-8 engine uses a system like

the diagram in this feature.

The passenger side mounted alternator has a very

long wire from the alternator to the main junction.

The junction is a “welded splice,” in the loom,

at the driver’s side.

The wire routing is a very long semi-circle between

the alternator and the junction.

And the “battery charging wire” is also very

long, to get from the junction back to the battery at the

passenger side. At

least in these years of Chevy cars, the alternator output

wire and the battery charging wire are both 10 gauge

wires. A 63

amp model 10SI works very well with existing wiring in

that system, and the factory built 78 amp 12SI will work

well with this system too. But remote voltage sensing from the junction should always be

used with up-grades to SI alternators.

When

adding electrical accessories with significant current

draw, and the SI alternators to this existing Chevy

system, it is very important that the accessories are

powered from the wiring at the junction–rather than

connected directly to the alternator or to the battery.

But the factory “welded splice,” hidden in the

wire harness is not friendly to work with.

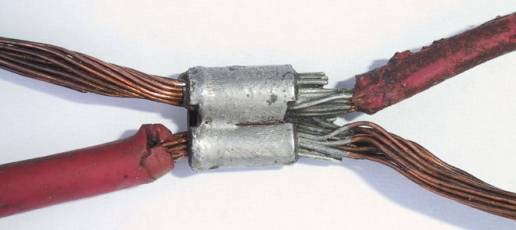

The

photo above shows a close-up view of an actual

“junction” from a Chevy wire harness.

Four red, 10 gauge wires were all connected

together, at what we have labeled a “junction” in our

system diagram. (The

GM engineering department refers to the junction as a

“welded splice.”

“Buss-bar” would also be correct terminology

with this discussion.)

This type of junction, hidden in the wire harness,

is very reliable, and it was economical to manufacture;

but it is not friendly for up-grade work.

The “junction” does not lend itself to system

modification or adding wires for accessories. The

insulated terminal block (part#CN-1, from M.A.D.) seen in

the photo below is a very friendly to work with

“junction,” and it should be used when up-grading this

system.

On the “flip side” of our

systems comparison, expect

that

with a 100amp ONE-WIRE alternator, wired directly to the

battery, and the same ’69-’71 Chevy wiring system,

performance of the electrical system parts will be

significantly reduced.

Wiring from the alternator directly to the battery

will charge the battery, but that could be done with a 37

amp alternator too. The

performance problem will come from “back-feeding”

power through the old charging wire to the junction.

Driving with lights and factory accessories

switched ON, we can have a 30 to 35 amp current load

through that 0.05 ohm resistance at the old charging wire.

And then we will have a 1.5 to 1.75 volt drop in

the old circuit, which is now feeding power to the

junction. This

situation would result with the junction delivering power

to various parts of the electrical system at only 12.45 to

12.7 volts, which is no better than just running off the

battery!

Also,

if we ever have the need to recharge a discharged battery

while driving, the ONE-WIRE alternator with a heavy cable

connected directly to the battery makes for a high rate

battery charger system.

And as previously discussed, fast charging

batteries can be destructive.

IN SUMMARY

We often need more

powerful alternators than the old cars came with, because

we are often installing items that use more electrical

power. But we

must do a good job of distributing the electrical power

from the alternator to the various parts of the electrical

system. And

while installing a ONE-WIRE with a heavy cable directly to

the battery will keep the battery alive, it does not

always do a good job of supporting the electrical system.

A powerful ONE-WIRE can also be abusive when

re-charging a low battery.

It’s obvious that the

properly wired THREE-WIRE ALTERNATOR can do a lot more for

us than the ONE-WIRE.

The comparison is in parallel with thoughts of

engine tune-up mechanics.

There are those tune-up mechanics

that are perfectly contented to work on slow, no fun or

frills, four door models–And never do more than change

spark plugs and other parts, and then verify that the

engine has no misfires.

(Although the engine may still be sluggish, or run

a little on the warm side when the spark advance and

air-fuel ratio is out of focus.) And

then other tune-up mechanics are most happy when

tuning an engine for maximum performance.

And they do very well at getting the most from an

engine. The

distributor spark advance system gets custom re-curved,

the carburetor gets custom calibrated, the valves get

properly adjusted, and so on.

The ONE-WIRE is like the tune-up that keeps the car

running, but does not optimize performance. The THREE-WIRE provides the option of getting the best

performance from the alternator.

The only

disadvantage of the THREE-WIRE alternator compared

to the ONE-WIRE alternator is that a little more knowledge

will be required to properly wire the THREE-WIRE into a

particular system.

At M.A.D., we have

that only disadvantage covered.

We do have extensive experience with wiring work

and electrical service on most of the popular models of

the older cars and trucks.

And M.A.D. prefers to sell alternator wiring kits

directly to the customer (and also many other of our

popular kits). It

gives us the opportunity to learn a little about how the

car is equipped. And

then if needed, we can customize the kits for best

performance and provide the most simple of installation

methods. The

factory wiring systems vary among the many makes, years,

and models. And

we have batteries at different capacity, and alternators

at different capacity, and various accessories that can

use only a little power or a lot of power.

Therefore, of course there will be times when we

need to customize the alternator wiring system.

(As with choosing a camshaft, there is not one

grind optimized for all applications.)

- Alternator wiring kits

from M.A.D. provide hook-up for original ALT and GEN

warning lights at the dash. We provide option for adding a Warning Light at custom dashes

too.

- And

when a system will benefit, we always provide the

correct hook-up for “remote voltage sensing”

function.

- M.A.D. also provides

the correctly calibrated Fusible Link wire kits for

short circuit protection.

(Fusible Links are the ultimate in reliability

for short circuit protection in High Amp systems.)

Fusible links should be installed in the

original dash area “main power-up” wire, high

current draw accessories, and at the alternator

system.

RECOMMENDED ITEMS FOR

ALTERNATOR UP-GRADES

- M.A.D.’s

part #ALT-1 alternator wiring kit or M.A.D.’s CS-130

alternator wiring kit.

(All the best of wiring parts, and great

installation & troubleshooting manuals are

included in the kits.

They are in M.A.D.’s catalog)

- Part

# TB-1, “tech is made simple” book

available from M.A.D. catalog.

It teaches craftsmanship techniques and has

other information needed to install custom wiring.

(especially important with High Amp systems, as

with alternator wiring)

- TOOLS

A good wire terminal crimp tool is of critical

importance with alternator wiring.

- PART

# CN-1,

insulated terminal block from the M.A.D. catalog is

the best part available to serve as the “main

junction,” when installing a custom version of the

system we have discussed with this feature.

COMING

SOON, from M.A.D.

We

are working on a parts kit for a new “POWER DISTRIBUTION

SYSTEM.” The

new system will perform equally well with ONE-WIRE and

THREE-WIRE alternators.

The system will work well with 63 amp model 10SI

alternators, or equally well with a 140 amp custom

alternator. The

new system will do a very good job of delivering power

from the alternator to the various parts of the electrical

system. And,

something that the industry has never attended to, the new

system will be gentle to the battery and the alternator

when working with these modern high-powered alternators

and accessories.

The

new system is simple to work with, and it has been proven

to be very effective. (We have already been doing it for many years, with custom

wiring and High Output alternators.

Many years ago it was the only way stock-type

alternators could last in abusive motor home

applications.) The

new system can be adapted to the factory-original type

wire harness, or it can be used with custom wiring

systems.

It

delivers full power to all parts of the electrical system.

And it will reduce the chance of alternator

overheating and “boiling” batteries, should a low

battery be recharged from a High Output alternator, while

driving. The

new system is an improved and more adaptable version than

the factory wiring discussed in this feature.

OTHER INTERESTING

READING RELATED TO THIS TOPIC

- See information with

M.A.D.’s part # ALT-1 kit, it’s in the M.A.D.

ELECTRICAL catalog at this web site

- VOLT gauge compared to

AMP gauge, in the electrical tech section of

M.A.D.’s web site (you’re in the M.A.D. site now)

- Visual identification

and features of the 10SI and 12SI alternators, and

“CLOCK” positioning of the wire connections.

(It’s also in this tech section of M.A.D.’s

web site.)

- AutoMeter for many

models of quality VOLT gauges, and discussion of AMP

vs VOLT gauges in the TECH TIPS/FAQ section, at www.autometer.com

- POWERMASTER for

ALTERNATORS at www.powermastermotorsports.com

ONE-WIRE move over!

ONE-WIRE move over!

The THREE-WIRE system is the winner

here!

The THREE-WIRE system is the winner

here!

|